- Is the correct Workset being used?

- Is the view range set correctly to see the particular element?

- Is the object hosted on an incorrect surface like a floor instead of a ceiling?

- Is there a filter applied to the view that is causing the element to be hidden?

- Is the detail level of the view set correctly? Some families are set not to show at Coarse.

- Try using the "Reveal Hidden Elements" tool in the view control bar.

- Is there a plan region in the view?

- Is the view "Discipline" set correctly?

- Is the element in the correct phase and is an appropriate phase filter set in the view to make it visible.

- Is the element part of a design option and perhaps that isn't the current option for that particular view?

Tuesday, January 25, 2011

Top 10 Reasons You Can't See an Element in Revit

Friday, March 30, 2007

Revit MEP Wish List now up and running

I'll also add this link to my side bar. All of my sidebar links to Autodesk pages have been updated in consideration of Autodesk's web site reorganization. Take a minute and peruse Autodesk's slick new look.

Wednesday, January 24, 2007

Kyle B. is taking over Revit Systems

I'm hoping to see the product fully develop in a matter of days now... so ah , no pressure.

Wednesday, January 10, 2007

Want to Crash Revit?

To avoid crashes for now save down to Version 5 before importing into your Revit Project.

Tuesday, January 09, 2007

Making Revit Systems Work

BIM

If you are wanting to switch to Revit Systems because you are feeling pressure to complete a BIM model, Keep in mind, nobody can agree to what the Hell a BIM model is. Seems like every one is working on it, but it is plain undefined.

That being said, someday we will know, and someday our contract documents will reflect the legalities of BIM. When that happens, my money is on Revit to deliver. Sticking your toe in the Revit waters now will acclimate you now so you are ready to jump when it's time.

My Architects are using Revit Building

This is a good reason to have Revit Systems, not necessarily a good reason to use Revit Systems. Having it means, I'm capable of translating Revit files myself both from and to the architect. The important thing to keep in mind for collaborating with your architectural clients is communicating what they can expect of you and developing new procedures in house to deal with a single Revit project file instead of multiple DWGs or DGNs. At this stage delivering HVAC and electrical content in model form for interference detection is a real bonus and a valid expectation. In the end producing coordinated CDs spending more time on design and less on drafting is the real benefit to MEP firms. Marketing that you have or use Revit Systems can get you in trouble if your client believe you have or can do something you can't (plumbing).

How Fast Can I get up to Speed?

I like the analogy of Revit products are like ipods. AutoCAD is record albums and ABS is CDs. There are people who love albums and will never stop. Transitioning to CDs is relatively easy for the user, they are just tiny digital albums. Transitioning to an ipod however is completely different. I think ipods sales would suggest that this is the way of the future, but I still read all about people still trying to figure out how to use the darn things. Once you do, you tend to love them.

If you want to get up to speed, understand it will be different for every firm, but here are the basics.

Find out what you don't know. Take a class, contact your reseller, research, do what ever it takes and allow your self time to understand what you are getting into. You will want to know what the software is capable of and what it can not do.

Plan. Decide what makes sense for your company. Just because the software may do something, your firm may not need to use that function. (Scheduling, Phasing...). Now plan out the purchases (Hardware and Software), the required content creation. Your firm will undoubtedly require objects not supplied with Revit Systems the same way AutoCAD did not come with Blocks or Layers, you will have to make them or pay a consultant to help you. Currently you probably need hundreds of families created and you may have no idea how Revit plots.

Educate. Your design team needs to learn how to function in the Revit interface. Not how to create templates and families, how to model and create construction documents.

Test. Validate what you have done on a small project. Something you do enough on that you can bail if you need to. Something you are comfortable quantifying. This will help you decide if Revit is faster, better, stronger.

Practice. I bet things are not all that faster or better on the first project, but as you continue to produce in Revit (tweaking as you go) Things will improve.

I Want to do what I'm doing now, only BETTER.In the end, this is the best and only reason to move toward Revit Systems for me. Yes, my clients use it, I heard the buzz about BIM, It's really cool according to my CAD guys... all things to consider, but oddly just wanting to improve your design process is what will really count in the end.

Friday, November 17, 2006

Overview of Revit Systems

Revit Systems debuted early this year giving MEP engineers a third choice of CAD technology to use; it may have also caused a bit of confusion on what software is really the best for any given firm. Having a choice is a good thing if you understand your choices. This article should help clarify the choices and provide a solid overview of Revit Systems.

What are the Choices?

No matter what software you are using, they fall into three general categories: digital drafting, object oriented and parametric.

Digital Drafting (AutoCAD)

Digital representation of classic hand drawn documents. Little or no intelligence in entities.

Object Oriented (ABS)

Objects contain design data that can be shared and extracted for use, some automatically, most manually.

Parametric (Revit Systems)

Single database of Building Information Modeling (BIM) ready data automatically updating changes and constantly in sync.

So why choose Revit Systems?

No matter which choice is made, there are external benefits as well as internal. The external benefits (BIM data) may carry more weight than the internal benefits (faster layout and sizing of systems) because our clients or owners are beginning to ask for them as part of the project. Even if it’s external pressure that is forcing a company to evaluate Revit Systems, the internal benefits are what will sell to MEP engineers.

Built on the Revit Platform

Revit Systems is part of a family of Revit products that provides unparalleled coordination, a simple to understand and use interface, and a revolutionary work flow that puts design first by automating drafting tasks.

Revit Systems does not have a drawing recovery function. This is because it doesn’t crash every day. One day you realize you have been working for months and Revit hasn’t crashed. It’s a good feeling.

A single project file per job enables a single depository for information. This allows for bi-directional associativity, which means that a change to a schedule reflects in the plan immediately. A detail’s callout will automatically update when the detail is moved to a new sheet. A single database can not be out of sync with itself.

Mechanical Advantages

Automatic layout of HVAC provides multiple routing solutions of ductwork routing based of locations of a HVAC system. Diffusers, ducts and equipment are simply assigned a system when inserted into the project. Like systems can be automatically routed by selecting them and hitting the tab key. Proposed routes are shown in a dashed line. Figure 1 mark 1. Use the Options bar to preview different routing solutions. Figure 1 mark 2. Then select Finish to complete the lay out. Figure 1 mark 3.

The longest length of a flexible duct segment that will be used in routing solutions in a selected branch duct system can be dictated by the user through the Mechanical Settings dialog box.

The System Inspector allows engineers to get critical data about a system by simply hovering over it. As the cursor passes over a selected system it can flag it with information on flow, static pressure, pressure loss, total pressure and excess pressure. See figure 2.

Room objects hold this and more design information that can be added to the information already in the architectural file then exported to Trane’s Trace 700 for load analysis by using the Export to gbXML function under the file menu. The information in room objects is shared across disciplines allowing for increased coordination between the electrical and mechanical engineer. See figure 3.

Sizing duct on the fly is assisted by the Duct Sizing dialog box. Sizing methods include friction, velocity, equal friction and static regain. The friction and velocity methods allow an “And” and an “Or” operator meaning duct can be sized for the best of the two methods or the two methods combined. See figure 4.

Electrical Advantages

Automatic circuiting works similar to the mechanical automatic routing function, reducing the time to complete electrical plans dramatically. Arc type and chamfered circuiting is available with tick marks on, off, or on homeruns only.

Estimated illumination is calculated based on the Room Cavity Ratio method and can be reported in schedules along with required illumination to help ensure design requirements are met. The scheduling function in Revit Systems can be set up to show the estimated illumination in RED if it does not meet minimum requirements for the room providing engineers easily recognizable feedback during every step of the design. See figure 5.

Similar schedules can be created for power and lighting loads per area.

Panel reports and schedules are also available. Possibly the most powerful tool electrically is the ability to rebalance panel loads with the push of a button. The reassigned loads automatically report the new homerun circuits on plans with no interaction from the user. See figure 6. The single project database of Revit Systems makes it possible to perform these calculations then update the entire project with new data and report back information engineers need like lighting levels, voltage drop, and lighting and power totals.

Combined Advantages

Interference checking in Revit Systems is as good as it gets. Interference checks can be run for electrical and mechanical, internally or externally, with Revit Structure or Revit Building components. A report is generated showing all interferences and any interference can be selected and shown in plan or model view in order to easily correct it. See figure 7. Automated section, elevation and detail cuts create these views as easily as placing the call out and they will remain linked if moved to different sheets. Flip a section cut call out and the section itself will reflect the new directional cut. While engineers may not need to cut sections often, when they do they are show-stoppers, requiring hours to complete with accuracy. Revit Systems cut them in seconds and they remained linked to changes in the model.

Automated section, elevation and detail cuts create these views as easily as placing the call out and they will remain linked if moved to different sheets. Flip a section cut call out and the section itself will reflect the new directional cut. While engineers may not need to cut sections often, when they do they are show-stoppers, requiring hours to complete with accuracy. Revit Systems cut them in seconds and they remained linked to changes in the model.

Revit Systems imports and exports to AutoCAD, MicroStation and Sketch Up formats directly.

The Other Shoe

So what should a potential Revit user be cautious of? Most notable, there is no plumbing component at this time. This is offset somewhat by the fact that Revit Systems is only sold bundled with Autodesk Building Systems which has a complete plumbing component but mixing a job that way rarely makes sense.

Required content such as lighting fixtures, heat exchangers and so on is minimal in this release. Revit family components can be added by the user, but take a solid understanding of families to create. New Revit Systems users will not be able to complete most jobs without creating families, and family creation goes much easier with training.

In addition to training consider hardware requirements, an initial productivity lag, and how well Revit works for your projects and with your people.

The Bottom Line

While Revit Systems has come out on a strong platform with some amazing tools, it lacks the substantial content required to be used everyday on every job.

Based on the aggressive release schedule of the other Revit products, Revit Systems could be ready for primetime in very short order. Keeping in mind how fast BIM and Revit Systems are evolving and the fact that Revit products are Autodesk’s BIM solution, the prepared engineering firm should already be planning and testing to be ready to deliver what our clients will be demanding.

Monday, May 15, 2006

New Carrier HVAC software imports gbXML

That software supporting a gbXML import has been;

Trane Trace 700 and VariTrane Duct Designer software

Elite DuctSize software

Green Building Studio

Now, Carrier has just released HAP 4.3. It now supports gbXML import. Follow this link for the details.

http://search.atomz.com/search/?sp-q=gbxml&sp-k=Commercial+Systems&sp-a=sp09127501&sp-f=ISO-8859-1

No doubt this will be good news for Carrier users that were contemplating a switch to ABS.

As an added bonus, ABS and ADT now share a common space object, meaning doors and windows come directly over from the architect and engineering design data can be added once in ABS without the loss of architectural openings. More to follow on that subject.

Sunday, May 14, 2006

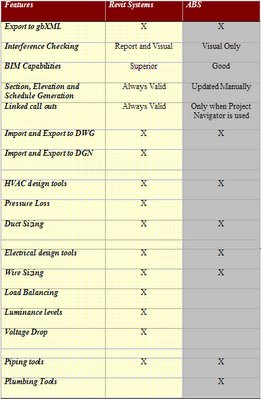

Revit Systems and ABS - a Comparison of Features

Today's post is simply a look at how they compare by major features. As you review them, you may notice the features in Revit Systems go deeper into the actual engineering of a building than ABS ever has. Next time I will be discussing why this is important as you look at your companies long range plans and procedures.

If you are having trouble reading the features list, right click on the list and select "Open Link". Once you see only the link, select the features list and click on the "Enlarge to normal size" button that appears in the lower right hand corner of the features list.

Thursday, April 27, 2006

AutoCAD vs. ABS vs. Revit Systems

Digital Drafting

Whether you liked AutoCAD, MicroStation, or whatever. (I was a big fan of Mac Architron.) The technology they all used was the same. Digital lines. We still drafted, but with digital lines. These lines could only be differentiated by color, linetype and layer. So we made a mess of layers to control them.

Object Oriented

Then came ADT and ABS. This was revolutionary. Instead of digital lines, new entities called objects were introduced on the AutoCAD platform that contained specific properties to the object type. Doors have properties like height and width, diffusers in ABS have properties for flow. These properties allow us to step away from layers for display control and give us a mechanism for linked scheduling of any object type. As an added bonus, these objects are three dimensional which gives us relational clean up when similar objects meet, like duct and pipe, and interference detection when differing object types occupy the same space.

Parametric Modeling

Revit Systems and Autodesk’s other Revit based programs take a giant step ahead of digital drafting and object oriented technologies by creating a relational model that can be queried for any type of view, schedule or detail. How many times have you heard draw it once? The minute you draw it twice in AutoCAD or ABS somebody changes one of two and now, there’s a disconnect. A Revit project has only one model. You can only draw it once, literally. Further, it does not matter which view of the model you modify, all views update because they are all referencing the same thing.

Let’s compare these three technologies in a little more detail.

AutoCAD 2007

Advantages

-Highly adaptive to most any drafting use.

-It’s the standard.

-Highly customizable.

-Large pool of qualified users.

Limitations

-It Crashes too much.

-Can’t complete against Autodesk’s vertical products.

-Requires implementation, optimization and administration to be truly effective.

Bottom Line

You know what you got with AutoCAD, it’s comfortable, but I can visualize a time when the building industry uses AutoCAD about as much as we hand draft now.

Autodesk Building Systems (ABS) 2007

Advantages

-It’s plain faster to drop in a complete object in a drawing that automatically connects to objects around it than draw line by line.

-ABS will draft AutoCAD into the ground when properly set up.

-The ability to import and export engineering data to familiar software for engineering calculations.

-Sections and elevations cut and schedules created in just seconds.

-Interference checking between ABS objects and ADT structural objects.

Limitations

-Familiar Interface lures un-trained users to fall back on AutoCAD tools and procedures effectively negating the additional cost.

-Near impossible to implement without an experienced consultant.

-Training is required to effectively use ABS.

Bottom Line

It's the best thing we have for MEP engineering right now. Knowing AutoCAD is not a free ticket to understanding ABS. It goes a long way toward reducing redundancies but still requires manual updates between related design components.

Revit Systems 1

Advantages

-Advanced Engineering capabilities include Load Balancing, Lighting Levels, Voltage Drop and Pressure Loss.

-Bidirectional Associativity.

-A single data base means I get accurate associations between all my data, all the time.

-I have never crashed Revit… Ever.

Limitations

-Did somebody forget Plumbing? Tap, tap… is this thing on?

-Very, very few qualified users. Those who invest in learning how to reap the rewards of Revit Systems will have to be compensated.

-This is the first shot out for Revit Systems, no matter what they got right, you can bet there is going to be a list of things that will need to be fixed or added.

Bottom Line

A true Building Information Modeling solution. If I am going to dream about where BIM can go, currently Revit products are the best the building industry has to offer.

If you want to be on the cutting edge, jump on now.

Wait much longer and you will be playing catch up while your competition is widening the gap between the future (everybody else) and the past (you).

Saturday, April 08, 2006

Along comes Revit Systems

Well…. crap.

What do I do now? Do I put ABS on hold? Am I wasting my time in ABS? What is the difference between the two? Where there used to be a clear direction there is uncertainty now.

We engineers are facing what architects faced back in 2002 when Autodesk gave Revit its first big push. I remember how they felt at AU that year, angry and confused. Autodesk is clearly telling us Revit is the future, yet I just bought and trained my entire staff on ADT. You jerks. Do you realize the efficiency drop that just happened? The training cost, the lost production? All for a software that is apparently NOT the future. Thanks a lot.

Well, time passed, and both ADT and Revit survived. Looking back it seems to me that there is room for and I’m sure Autodesk is banking on a need for both platforms. ADT is still going strong. Revit Building is growing in popularity. For that matter, AutoCAD still dominates the much of the market.

The real question now, is which one is best for your firm. I know the answer.

“It depends.”

It’s not a cop out. It’s just the way it is. While we are all out there providing the same service, we all get there different ways. We all have a different talent in our staffs, different cultures, and different business plans. To find the software that best suits your firm you are going to have to do your home work. You will need to consider your business, your people and your process and make the best match to the available software.

You know your firm. I’m going to do my best in my next couple of posts to differentiate AutoCAD from ABS from Revit Systems. Hopefully, it will help you match the best technology to your particular firms needs.